Floriculture Company Saves 18.26% on Energy Bills with No Up-Front Costs

Best.Energy Kenya, took the lead on an exciting new project with Subati Flowers Naivasha, a flower grower and distribution company, looking specifically at optimising water pump functionality, assessing cold room cycles and controlling greenhouse humidity and temperature.

Kenyan flowers are sold in more than 60 countries, and it’s estimated that over 500,000 people depend on the Floriculture industry - impacting over 2 million livelihoods. Best.Energy Kenya made contact with Subati Group with the overall intention of gaining better visibility on their site consumption and lowering rising energy bills.

With roses grown in greenhouses spanning over 50 Hectares at an altitude of 2,200m above sea level, understanding the sensitivity of the flowers to their environment is critical to reaching international floriculture standards. Best.Energy Kenya got to work analysing the client’s key assets to spotlight pain points and advise on implementing a suitable solution. After installing CUES units to optimise the refrigeration systems, the minute-by-minute data revealed savings of up to 30% on the Cold Room lines. In addition, Air Sense has been introduced, an environment sensor to capture data on light, humidity, temperature and occupancy that led to further reductions in consumption and increased productivity.

What are the project headlines?

The work executed on the first site provided a convincing case for roll-out across the two more sites in Kenya:

- Total savings on site at 18%

- Total CO2 reduction of 1,744 tonnes

- Total energy visibility across the site down to asset level, identifying waste

Best.Energy Kenya were able to deliver Subati savings within just 4 short months, enabling them to provide a comprehensive sustainability report to the likes of the Flower Council of Kenya and other certification bodies.

What have the results of the project been?

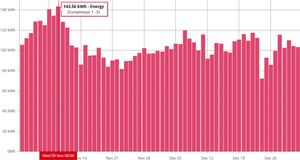

To demonstrate the impact the CUES unit has on Subati’s assets, take a look at the graph below where the marker indicates reduced consumption levels in the cold room compressor. This decrease contributed to sitewide savings of over 18%, approximated at $30,000 worth of savings per annum.

Going Beyond Energy Saving

“This has been a hugely rewarding project for us so far - to see not only the impact we’ve been able to have on energy savings, in a landscape of rapidly rising prices, but also to be able to positively influence the growth of these beautiful flowers. We look forward to rolling this solution out across more of Kenya’s 70+ flower farms”

Ivan Seka, Operations Director Best.Energy Kenya